American building systems are constructed in many different shapes and sizes for many applications, from manufacturing and distribution centers, retail and commercial facilities, offices and schools, recreation centers and self-storage facilities, to healthcare and correctional institutions. American Buildings Company has the advanced design, engineering, and manufacturing capabilities to be a single-source supplier for a wide range of metal building systems. American accomplishes this by offering a variety of building styles, framing styles, column shapes, and girt conditions that can collectively satisfy virtually all building requirements.

Building Styles

Building styles offered by American include three common designs. The Gable Style (GS) provides a traditional center ridged-roof slope available in a variety of pitches. The Single-Slope Style (SS) has similar characteristics of the Gable Style but in a single-slope configuration. The Lean-To Style (LS) resembles the Single-Slope but provides an economical means of making a building wider by extending its roof line or it can be attached to a lower level on the building to provide additional office or storage space.

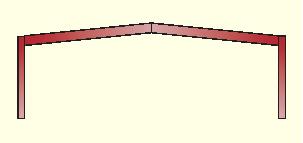

A Gable Roof System (GS) provides a roof with two sloping sides and a ridge. With optional tapered columns, this  style of building is a cost-effective solution for office, warehouse, industrial, and commercial applications. The available straight column option provides a good system for palletized storage or display racks and is also ideal for shopping centers and other commercial buildings. The girts can be located in either a bypass or inset position and the roof slope can be as low as 1/4:12 or as steep as 6:12. The Gable Roof System is available with clear span frames or with interior columns, which provide economical solutions for wide buildings.

style of building is a cost-effective solution for office, warehouse, industrial, and commercial applications. The available straight column option provides a good system for palletized storage or display racks and is also ideal for shopping centers and other commercial buildings. The girts can be located in either a bypass or inset position and the roof slope can be as low as 1/4:12 or as steep as 6:12. The Gable Roof System is available with clear span frames or with interior columns, which provide economical solutions for wide buildings.

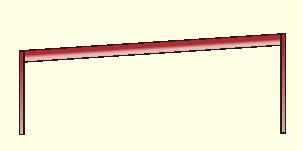

A Single Slope System (SS) provides a building with one roof surface. With single-side drainage, these systems are suitable for manufacturing facilities, warehouses, and retail shopping centers. The available tapered columns provide an inexpensive solution for wider buildings, while the available straight columns allow for maximum usage of interior space. The girts can be located in either a bypass or inset position and the roof slope can be as low as 1/4:12 or as steep as 6:12. Clear span frames are available or interior columns can be added to provide an economical answer for wide buildings.

A Single Slope System (SS) provides a building with one roof surface. With single-side drainage, these systems are suitable for manufacturing facilities, warehouses, and retail shopping centers. The available tapered columns provide an inexpensive solution for wider buildings, while the available straight columns allow for maximum usage of interior space. The girts can be located in either a bypass or inset position and the roof slope can be as low as 1/4:12 or as steep as 6:12. Clear span frames are available or interior columns can be added to provide an economical answer for wide buildings.

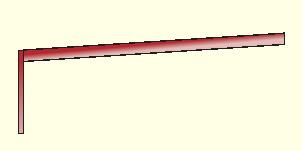

A Lean-To System (LS) provides a cost-efficient means of making a building wider by utilizing a single slope system to extend the roof line of a building or by attaching to a lower level on the building. This is ideal when additional space for office or storage is needed.

system to extend the roof line of a building or by attaching to a lower level on the building. This is ideal when additional space for office or storage is needed.

Column Shapes

Column shapes are determined by several factors, including a building's required roof slope and interior clear spans. American provides two styles of column shapes. The Tapered Column is normally found in buildings where interior finishing is limited, such as warehouses, distribution centers, and storage facilities. The Straight Column allows for interior walls and maximum use of interior space.

Framing Styles

There are two primary framing styles found in American's building systems. The Rigid Frame is the most economical style for clear span and modular widths. It is normally used in buildings where higher center clearance or greater roof slope is desired. The Girder Column Frame offers straight wall columns and inset framed girts. This style offers extreme widths and the lowest roof slope possible.

Girt Conditions

Girt conditions refer to the method in which horizontal girts are attached to the exterior columns in a building. The most common condition, the Bypass Girt, makes a continuous run around the outside of a building’s columns, providing an air space the width of the girt between the column and the exterior panels. An Inset Girt minimizes the air space between the columns and exterior panels. Flush Girts provide no air space between the columns and exterior panels yet offer the maximum amount of floor space.